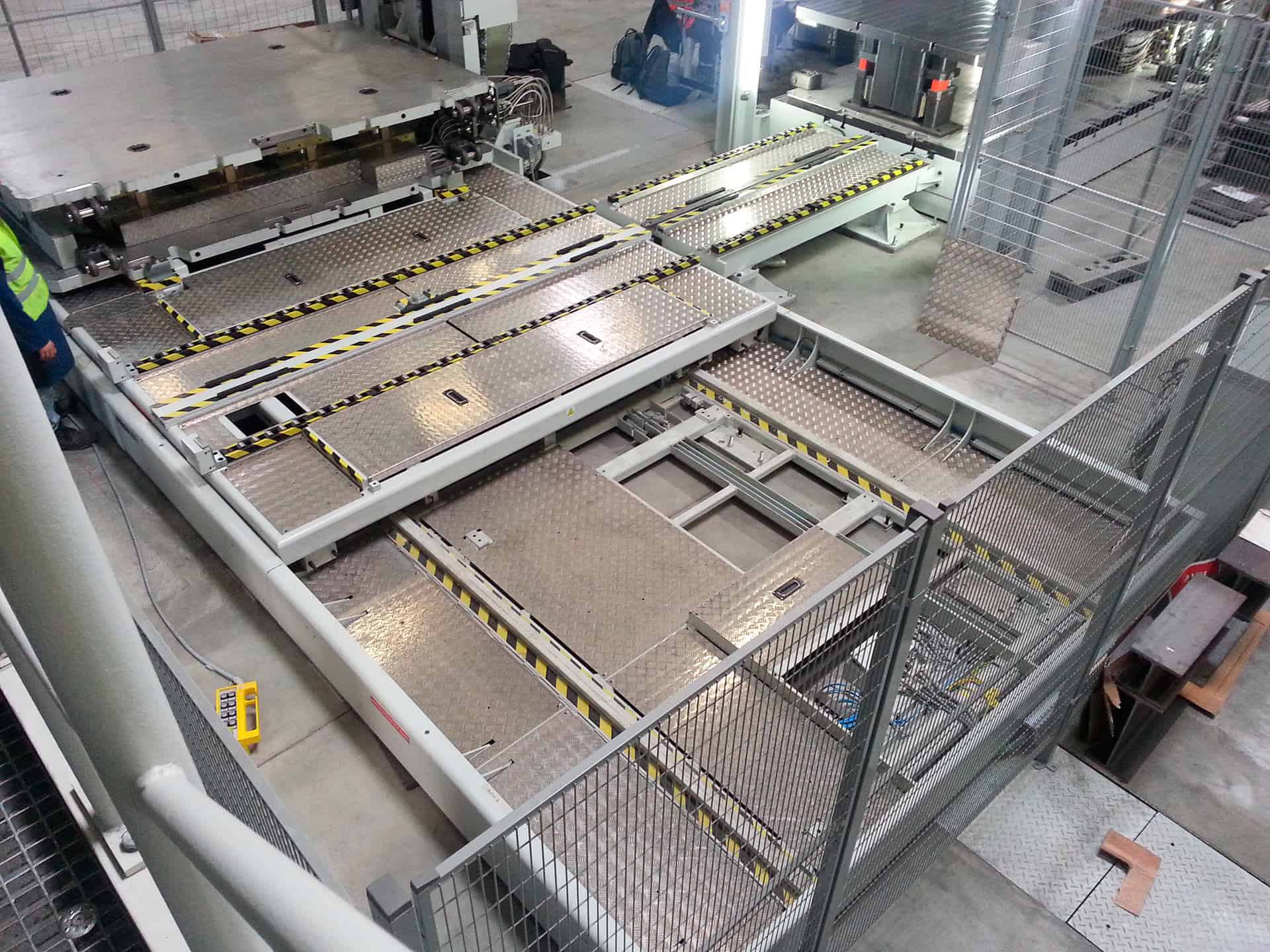

To automate 7 production lines for BMW, the car manufacturer, Dieffenbacher used SERAPID for the quick die change system. Each line is equipped with one or two presses with 20 and 40 tonne dies.

A new SERAPID system was designed to include the cart rails into the structure fixed to the ground, making it possible to avoid major civil engineering works and to save time during installation.

Automated die change improves productivity. The QDX SERAPID double work station system guarantees die changes in only 4 minutes.

Quick Die Change on a car production line

Dieffenbacher specialises in presses and composite fibre and reinforced plastic production processes. To automate 7 production lines for BMW, the car manufacturer, Dieffenbacher used SERAPID for the quick die change system. Each line is equipped with one or two presses with 20 and 40 tonne dies. A new SERAPID system was designed to include the cart rails […]

Client: BMW Group

Location: Dingolfing, Germany

Characteristics :

- Load:

- up to 40 tonnes

- Speed:

- 150mm/s

Dieffenbacher specialises in presses and composite fibre and reinforced plastic production processes.